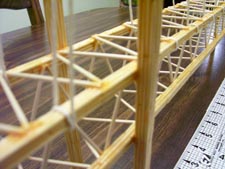

I just finished this bridge a few days ago after working on it on and off for 3 months. It’s a cable stayed bridge design made with standard round toothpicks and wood glue.

The bridge is 31 inches long and just under 20 inches tall. The main road truss is 2 inches by 2 inches, constructed of beams of laminated toothpicks (3×3) and held together by individual toothpicks in a triangular truss pattern. The towers were constructed of laminated toothpick beams as well, but thicker (4×4). Then the suspension was created with 4 strands of thick string wound back and forth across the top of the towers.

I didn’t make this for any particular occasion or contest; I just wanted to see if I could make a sturdy suspension bridge. I’ve built a toothpick bridge before. It won a contest by supporting 350 lbs. over a two foot span, but obviously it was destroyed in the process. I don’t plan on testing this one, although I imagine that someday my curiosity will probably get the better of me. Besides, I really don’t think this bridge will hold nearly that much weight. I’d love any comments or pointers you guys might have. Enjoy!

There are a few more pictures of this bridge (higher resolution too) on my Flickr photostream at http://www.flickr.com/photos/razokylava/ I’d love any comments or pointers you guys might have. Enjoy!

This is a beautiful bridge! Thank you for sharing. My natural instinct is to encourage you to test it, but it would also be a shame for it to get destroyed.

It’s getting kind of tough because my natural instinct is to test it too. Every time I look at it my brain starts making rough calculations of how much weight it could support. I’m not sure if I’ll be able to resist the impulse much longer, but if I do give in I’ll be sure to post the results.

sir plz can you tell that how much weight it can bear…. or what are math work of this bridge

Beautiful I cant wait to build my own

Wow… A whole 3 months??? If I really had the encouragement I could finish something like that… But otherwise I wouldn’t even come close…. It is a beautiful looking bridge :D, I’d think of that as a work of art 🙂 Nice Job done 😉

thanks 4 the idea but i can’t use string on my bridge. i can only use toothpicks and glue☺

thats awesome but will it take less time to make it if i do it every day because its for my science fair i want to use this idea but it might take too long

hello i love this bridge and my friend and i made it hold 600 lbs

great,

I have participated in a contest in which i have to make a suspension brige out of props of ice cream. so i have inspired from this and it will really help me while building my suspension bridge.

this is not a real toothpick bridge because it is made with other wood sticks

wah wat a wonderful bridge u have done really its superb done within 3+ months its really great.

the title of this says toothpick suspension bridge but i noticed you said it is a cable stayed bridge, now i know they’re very similar but i have to build a model suspension and beam bridge for my science project and i didn’t know how to make a model suspension bridge. i got a sort of idea from your model but if i make something similar (don’t worry i wont copy your idea) would it be considered a suspension bridge? I’m testing the strength of a suspension and beam bridge to see which is stronger so its crucial to my project.

dude that was awesome. I want to make a strong brdge 4 my class. But I don’t know what kind of glue to use.

Sweet, I had to make a bridge out of spaghetti for science. I believe mine had a 36.9:1 weight held to weight ratio. Mine could have held more but I botched the dimensions because I was OCD and kept chopping millimeters off the ends of the spaghetti so each piece would be even. I was .5 cm short of 1 foot and the bridge had to be at least 1 foot, so I had to hastily glue what little spaghetti I had left onto the end, and that is what broke. We couldn’t use string though 🙁

Anyway. If I recall correctly you should make each string looser. It will hold more weight that way. Its the same principle behind that of why a person can hand from a vertically suspended clothesline but not a horizontally suspended one. The way a string/cable is designed makes it so it can support MUCH more weight when stressed vertically than horizontally. That is why the cables on suspension bridges are so loose, and not tight (suspension, not cable stayed), so there is more vertical support as opposed to horizontal.

I’m actually remaking a bridge for a project in that class and analyzing the individual design components.

Awesome one 🙂 it really just took 2-3 days for it for me. i made it for my Science fair ! thanks for the idea 🙂

Looks great! But I suspect it would not carry much load at all (so you shouldn’t bother testing it).

Center-point loading will cause an inward load at the top of the towers. You have attempted to brace the top of the towers against this inward load via the strings to the backspan of the bridgedeck. But this only increases the bending moment in the bridgedeck, and fails to provide adequate support to the top of the tower.

If you loaded your bridge, the bottom chords of your bridgedeck will snap quickly at centerspan, and your two towers will fall towards eachother. Try it – take a video – and prove me right!

Wow, i am building this bridge for math with my partner lol can u gimme any tip? at all? lol

This looks amazing! I wouldn’t have guessed it took 3 months, it would probably take much longer. It actually does look very professional, so congratulations on making something this detailed!

this is fantastic!!!i thought that it would take at least 5 month to build.congratulations!!!

great im doing my senor on suspension bridge. Perfect product. Thanks

wow that is amazing!

YOU ARE A GENIUS!!

Technically, this is a Cable-stayed bridge. The cables run straight from the towers to support the roadbed in your bridge. A true suspension bridge would have one cable running from an abutment on one end up to and across the towers and into another abutment at the other end, with more cables running down to the roadway to attach them to the initial cable. But this is very good and I suspect it is very sturdy.

very good 🙂

We need to make a 1.5 m suspension bridge. We dont know what materials were gonna use. It needs to carry a 2 kg item for 10 seconds.

wow. can that hold up a brick? if it can, than i might try to do it. it can give me an A.

Very accurate and interesting work. Nice to see.

I want to ask you to do a new design (new type) of suspension bridge with a large span.

Suspension cables are anchored at each end of the bridge. The load that the bridge bears converts into the tension in the cables and is transferred to the support bases.

Cables stretch beyond the support bases up to the dock-level supports further to the anchors in the ground. The top tether system keeps stove roadway, bear the weight of the deck, and transmits the weight roadway through struts on the lower cables.

One advantage of this bridge design is that it can span long distances and resist earthquakes. It requires less construction material, which reduces its cost of construction.

I think that, this type of rope bridges could be called a “green bridge” judging by the favorable opportunities in the construction of such a bridge – substantial reducing the amount of materials (cement and reinforcing steel), which are now being spent at the device numerous concrete supports and pylons for modern large-span bridges. And after all, the production of cement and steel production – are not only energy intensive, but also extremely environmentally unfriendly.

This type of bridge is actually called a cable-stayed bridge, but I think that is is very well put together. I hope to see a popsicle version of this type of bridge.