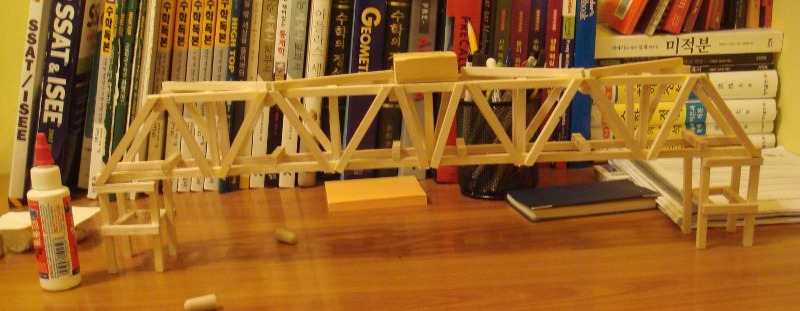

Hi this is Hyun Seok Yoon. As the title says, I just made my first bridge for the science olympiad!

Although it took me 12 hours (whew..!) I could see the good result! It held 15kg!

I saw some other members’ bridge and recognized that the height and span things were different from our rule which is held in New York.

But there is one little problem. My bridge weighs 111g. I don’t understand why. I used balsa wood and bass wood both and only used 1/4×1/4 size. I think using only 1/4×1/4 is the main problem. I can’t upload the picture somehow, so I uploaded them separately. Please help me reducing the mass. Also, when I was

testing the bridge, there was a cracking sound. Can you tell me what that sound means?

It would be great to get advised from all of you.

If you are using 1/4 square pieces of Basswood, that is WAY too big. You can definitely reduce the size of your members a lot.

It is hard to say what the cracking sound was without examining the bridge. Look closely to see if you see any broken pieces.

One thing I would add to your bridge is some diagonal bracing on each end of the bridge. You have zig-zag bracing on the top of the bridge, which is good. Continue that down the ends of the bridge.

i don’t think u can put 10 by 10 block through it

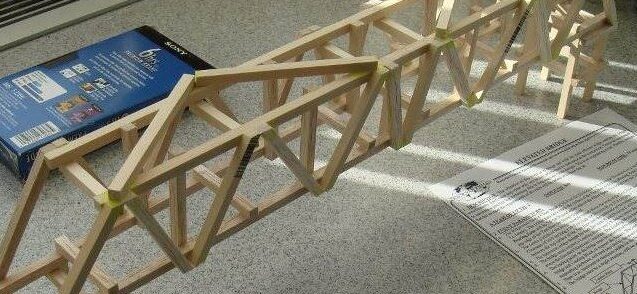

For the horizontal members, I suggest using 3/16 inch balsa (which is in between 1/8 and 1/4.) For the trusses, (very) thin basswood or balsa would work well. For basswood, this would be about 1/8 by 1/16. For balsa this would be about 3/16 by 3/32. It appears that you could also reduce the number of trusses by about 20% without loosing too much strength.

The cracking sound was likely the braking of one of the trusses. It can internally break without too much damage evident. You should try to build the bridge in such a way that if one truss falters, the entire bridge will fall. If this is not the case, the truss is simply extra weight.

In addition, add some members on top of the bridge to prevent twisting as the bridge gets lighter.

So in summary:

-3/16 inch balsa for the really important parts of the bridge (top and bottom beams)

-3/16 by 3/32 inch balsa for the trusses (or 1/8 by 1/16 inch basswood)

-Add diagonal braising on the top.

-Consiter using gorilla glue or diluting the wood glue with water (haven’t tried myself, but I have heard that it help the glue penetrate farther into the balsa.

I think that you could bring the weight of the bridge down to around 25 or 30 grams by doing this.

Btw, are you sure that the bridge has enough clearance?

First off, your trusses aren’t going to do much when they’re on the outside. That puts all the stress on the glue, instead of the wood. Put them inside, so that the 45cm horizontal is on top, and the one on the bottom, is on the bottom. This transfers the stress to the wood itself, instead of the joints.

Actually, the use of Lap joints is a very intelligent building choice

http://www.garrettsbridges.com/building/bridge-joints

Here’s a resource discussing the strengths and weaknesses of a couple different joint types.

I would surely say that 1/4 is too large for any application in the scioly elevated bridge challenge. Personally, I have been using 1/8 as my largest member types and using 1/16 and 3/32 pieces for less important members.

HI, this bridge is very pretty! I like it! you’re a good bridge builder!!!