The Warren Truss is a very common design for both real and model bridges. It’s exact history and origination is a little muddled, however. James Warren patented a design in 1848 (in England), which many attribute the name “Warren Truss”. His patent was more about the methodology of building rather than a “design”. Regardless, the Warren Truss has been around a while and has been very popular. Examples of it can be found everywhere in the world.

The Warren Truss uses equilateral triangles to spread out the loads on the bridge. This is opposed to the Neville Truss which used isosceles triangles. The equilateral triangles minimize the forces to only compression and tension. Interestingly, as a load (such as a car or train) moves across the bridge sometimes the forces for a member switch from compression to tension. This happens especially to the members near the center of the bridge.

How the forces are spread out

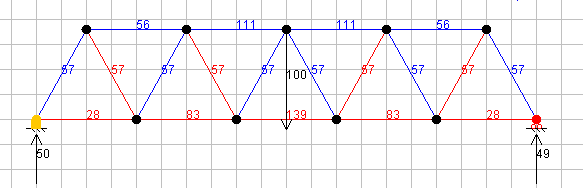

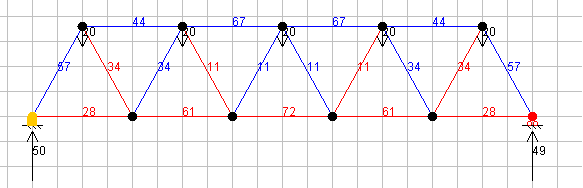

Here are two diagrams showing how the forces are spread out when the warren truss is under a load. The first shows the load being applied across the entire top of the bridge. The second shows a localized load in the center of the bridge. In both cases the total load = 100. Therefore, you can take the numbers as a percentage of the total load.

Interestingly, there is a significant difference. When the load is concentrated on the middle of the bridge, pretty much all the forces are larger. The top and bottom chord are under larger forces, even though the total load is the same. Thus, if you want your school project bridge to be able to hold more weight then try to spread out the force across the top of the bridge.

For a real life Warren Truss bridge, the forces often will be very localized and not spread out along the bridge. Thus, engineers must calculate how strong to make each member of the bridge and build accordingly. Unfortunately, not many Warren bridges are made anymore.

Warren Truss for model bridges

I have definitely used the Warren truss design for many balsa and basswood bridges. I have also used for some popsicle stick bridges. In fact, you can get a learning kit using a Warren Truss from my store. I think the Warren is a very solid choice when designing a model bridge. If you do not know how to start designing your own bridge, I would recommend the Warren, or the Pratt or Howe trusses.

The Warren truss is easy to use with Lap Joints, which are very strong joints. Find out more on my Bridge Joints page. All you have to do is lay down your top and bottom chords, and glue on the truss members directly on top of the top and bottom chords. The example bridge that I build in my 5 Steps to Building a Model Bridge ebook is a Warren Truss design.

Additional Resources

Pictures of real Warren Truss Bridges

In depth history of the Warren Truss

With a center load (which I have for my project), how am I supposed to distribute the force across the top?

I also have a center load project for Tech.and i also am wondering how to distribute the weight across the top.

Currently we have middle school project on Warren Truss Balsa bridge, How did you managed the load to spread across the top , bottom chords . We are only able to get 10 to 12 lbs most . How can we increase the load on to the bridge . Have to use only Balsa wood and did lap joints . Appreciate your help . We will be heading to states shortly . So need your inputs . Thanks .

You can spread the weight by extending the truss system above the single span pictured on this website, i.e. make the bridge a triangle. You can continue the design upwards, shortening each successive span by two equilateral triangles, until you have a central triangle which transfers forces downwards onto the base span. This will obviously increase the mass of the bridge and place extra load on the base span, but will spread the load 🙂 Hope this helps.

I have to do a science fair project to see what bridge designs hold the most weight. I want to test the best. 🙂 Can you tell me what are some of your favorites? Thanks!

truss bridge for sure

i agree that truss is the best

i agree as well

i love this i might get an a on my project

I like the suspension bridge.

I have a tech project and I’m trying to find the easiest bridge to build. Not that I’m trying to take the easy way out, but what do you think about this? Would it be a good choice?

I’m doing a tech project and we have to make a truss bridge and test it, are Warren trusses good??

hi, i have to do a tech project too, from what i have found, Warren trusses are the best.

yes they are great

I’ve done 2 bridge building project and have used the warren truss model for both. I think it is very effective and would definetly use it again

how do i calculate the forces on each member just using a calculator?

bob,

what grade are you in and what level of math can you do? some trigonometry is needed to calculate the forces. can you do trigonometry?

I am doing a project for school, we are making a bridge out of skewers i need some help and ideas! Thanks 😀

this web site is amazing! helped me out a ton 🙂

Hi guys! I have a project for science and we need to make a bridge out of skewers and straws. We only have 40 skewers and i need a strong design that can hold its weight x4! If anyone can help me find a design that includes warren trusses that would super duper helpful!! 😀 xx

clair,

having participated in a few model truss competitions while in college i can offer a few words of wisedom.

1, carefull clean construction with good joints goes a long way

2, most likely failure mode will be the joints or in compression. so make good joints

since this is a science project think about bucking and do some simple tests.

3, shorter is better for compression, long and thin is good for tension. this will enable you to optimize the design.

withadditional details on the span, width and materials I can provide more advise.

Hi, I will be doing this for a physics CP project that will be due in a week. From what my teacher has explained the weight will be held from the center of the bridge and not spread out equally throughout the bridge. Which design of a truss bridge would you most recommend for this project? We will be graded based on how much the bridge can hold, and how much the bridge islet weighs. I would appreciate any help you can give me.

Regan, use the Warren Truss bridge design, I have recently done an engineering assignment where we had to make a light weight bridge out of balsawood and see how much weight it could take then our strength/weight(bridge) ratio was calculated. the warren truss bridge I created weighted 120g and held 19kgs… I also did another type of bridge that was heavier and only held 15kgs. I would thoroughly reccomend an Warren Truss Bridge, hope this helps 🙂

We have to build a Warren Truss bridge out of tooth picks :O

We did too! It was so hard to design and to build!

yayv i hate stem

thank you for this!! well, we have a project too, we will make a bridge out of pasta 🙂 but i think this is easier than others :))

We have a requirement on our Steel Design, I’m going to design a bridge using warren truss, 2 lanes and 4 spans. What should I do first?

design the body of your bridge first and go from there

I was wondering if you had anymore info on the Neville truss

Hello, I have to do a basswood bridge project for school. I was planning on using a Warren Truss for my project but I am unsure, because the directions say that the load will be administered from a loading point that will hang down from the bridge. If the load is hanging down from the bridge should Is still make the bridge short and long, or try use a different design?

the designs that truss made are awesome and i agree to them in so many ways

Hi,Im doing a tech project aswell and I used the pratt.

This post was super awesome and the whole website in general was great. I’m a senior in high school and in my AP Physics class after the AP test we spent a week building bridges out of balsa wood. The bridge had to spam a 10 inch gap and was loaded from the top. Max height was 3 inches and max width was 2 inches. We built a warren truss with 6 bottom segments and 5 top segments. The load was placed in the middle of the middle top segment. We used Loctite glue for the joints. The bridge was 12 inches long and a little over 2 inches high and about an inch and three quarters wide. The bridge weighed 9.92 grams and held 20.2 pounds. The scoring was kilograms per gram and the score was 0.92 I believe. It was our first time building a bridge for a competition like this and we couldn’t have done it without this website. We used small gussets on our joints for both the truss and cross members. We also set the record for all time best bridge in the class. The balsa wood we had to use was 0.125 in by 0.125 in. The segment of the top that had the load used an extra piece of balsa to reinforce it because the load was not on a joint and we were afraid the balsa would break.

Great job, Patrick.

Pure awesomeness, Patrick

It is great it helped

This is a clear design and I have used it for many projects and is has not failed once

Could you tell me why do you always apply forces at the top joints? In real life, as I understand, only bottom joints are loaded.

Peter, this has to do with the ease of loading from the top verses loading from the deck of a model bridge. The theoretical load distribution doesn’t change based on top or bottom loading.

does the warrent bridge have a solid road bed

The Warren Truss is amazing!

How much weight can a warren truss bridge made out of popsicles hold?

A lot! A Warren truss is a great design and works well in model bridge made out of popsicle sticks and other types of materials.

It works well made out of balsa wood, too. Over 20 lb!

will the amount of trusses on a warrent bridge that is the smae length affect how much it can hold?

How much weight can a warren truss bridge hold if it is made out of straws?

what do all those numbers represent in the diagram and why are they of that value/ how do they add up??

we are trying to find something that will help with our science fair project. Our question is what size truss on a thirty centimeter bridge suits the bridge the most. if anyone could help we would appreciate it

hello cole, im glad to know that you are working so hard on your science fair project. To answer your question cole A thirty centimeter bridge should have a number that is easily divisible by thirty, in order to have a even amount of trusses that will cover the whole bridge. Thirty is a good number to pick, because all the numbers divisible by it are good picks for an experiment.

Hello there, I am doing some research for a TV programme about the history of the Warren Truss bridge.

I am looking for a standout example of a Warren Truss bridge that is still in existence. Do you know the oldest/first/longest/biggest Warren Truss bridge in the world? Or another notable one. The only stipulation is, it must be a Warren Truss to be exact.

Any advice greatly appreciated… thank you!

Hi Andrea,

I don’t know off the top of my head what would be a good bridge for you to feature. However, you can browse this website for noteable Warren Truss bridges:

http://bridgehunter.com/category/tag/warren-truss/

I just wanted to say that your web site has helped me a lot and probably always will

I think this information wasn’t that helpful. What sites can I use for background information about Warren Truss Bridge Designs?

I need help with some info fro the Warren Truss Bridge. Can you help me?

Hey I need some help on a project and I hope someone can help me out so my question is how much does an average warren truss bridge cost?

Hi there,

I don’t understand what these numbers mean. Do they mean the newtons of force? And also why is there the number 139 on the bottom closest to centre?

Joe,

The numbers in the truss analysis pictures represent a percentage of the total force. They are not associated with any specific unit, like Newtons. Instead, because they are showing a percentage, you can substitute any unit in their place as long as you are consistent.

So for instance, let’s say there is a 100 Newton force pushing down in the very center of the bridge. The bottom red member that says “139” now means that there is 139 Newtons of force pulling on that member (red in this case shows tension). How can this be if the total force applied at the top is only 100 Newtons? This is because the design of the truss sometimes multiples the original force in certain members.

Hi there,

Because of you helping with this, the team I am in have won the bridge building competion.

Our bridge, decided with the help of this website, got a paddle pop stick and hot glue bridge that held up 0.112kg per gram of bridge, and held up 20kg overall!

We flattened the competition, who’s best was 0.29kg behind.

So basically thank you.

Congrats!

Would the numbers be the same if the center load was supported from the base of the bridge construction?

Yes, it would be the same.

Hi, can anyone help with this question? Where is the longest single span Warren bridge in the uk? And how long is the span?

It will not be the railway bridge over the river Severn in the centre of Worcester which has a mid span support but it is an illustration of a classic Warren girder.

Why did James Warren make the Warren truss bridge?

I imagine that he thought it was a better way to build a bridge.

its because it uses less materials than the other designs that were made in the 18th century

I am using this site to help write a report on truss bridges and you have awesome information here. Is there any way I can find the resources that you had used through the making of this site? Thank you.

Where was the first Warren truss bridge build?

hi! I would like to know if Warren Truss Design is applicable in bridge 100meter long.

This is wrong, you should have only used the reaction forces of the individual forces. no wonder there is more compression and tension on the members. LOL

or*

I am doing a science fair project for a bridge project with my friend and we are wondering if a howe, warren, or pratt truss would work best covering a 24 in. span.

I think that the warren would be better.