What is the strongest bridge design?

This is the question I get asked the most.

Before we can begin to look for an answer, I need to know more specifically what you are looking for. Are you looking for the the strongest Type of Bridge, such as:

- Beam

- Arch

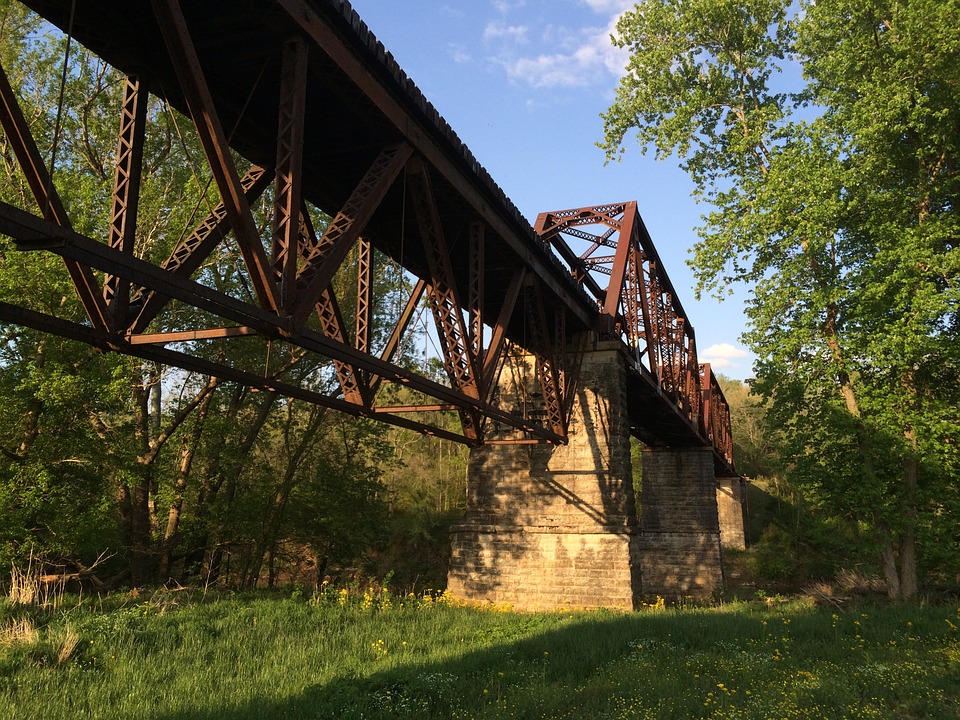

- Truss

- Suspension

Each of these has advantages and disadvantages. Each type could be the best for a specific situation, and there are a ton of factors that engineers must consider when choosing which one to use.

You can learn more about each of these by clicking the link above.

Perhaps you are asking about which truss design is the strongest. Since most model bridges are truss bridges, this is a great question to ask.

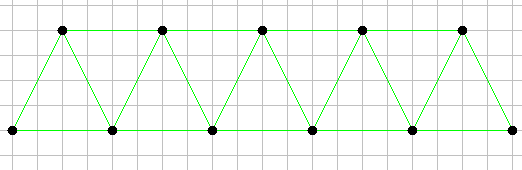

- Warren

- Pratt

- Howe

- Many More

Is the the Pratt, Howe, or the Warren truss stronger? Each of these designs, along with the host of variations, was developed for a specific reason or to make better use of existing or new materials or construction methods. Their history is fascinating, and you definitely should check out the articles about each of them.

Each truss design takes a load or force and spreads it out, eventually transferring it to the bridge abutments and/or piers.

So Which Truss is Strongest?

You really are going to pin me down to answering this question, aren’t you?

In my mind, none of these truss designs has an inherent advantage over the others in a very broad and general sense.

However, when we are considering small model bridges, I have a hard time seeing the Howe as efficient as the Pratt. But is one of these better than the most common, the Warren? You can explore my reasoning on this throughout this website.

Why don’t you take a look at each design and comment below which on you think is the best, especially in the context of model bridges.

In a specific case, such as the truss spanning 15 inches with a single constantly increasing force applied directly in the middle (7.5) inches from the ends, which would be the stronger truss, assuming that a limited amount of material is used. I guess the better question is given a specific amount of material, what is the optimum truss design. Also for the truss members, would a round, square or rectangular tubing be stronger, again the material is limited.

Lil Roy, personally I prefer the Pratt truss. I have had good success with it. Do you have to use tubing? Tension members do not need to be anything other than flat pieces of wood. Compression members can be made more efficient if they are in an I or T shape.

i myself prefer to experimment with combining different desingns and i hav held over 100 pounds on a six ounce bridge withmy technique

Thank you for not specifing a certain bridge because i know that you would be flamed horribly if someone didnt agree with you. I agree with you 100%! Well Done!

what is the modulus of elasticity of popsicle sticks

Ralph, I don’t know the modulus of elasticity of a popsicle stick. But I imagine it is not consistent, because of the total lack of quality control with popsicle sticks. For the most part we don’t even know what wood popsicle sticks are made of. Thus, knowing the modulus of elasticity would not really be helpful. What is more beneficial is simply sorting through and finding the popsicle sticks with the best grain and least deformity.

i have to construct a bridge that is exactly 7 inches long. i will be given 25 miniature wooden beams that are 7 inches long themselves and i can cut and put the mtogether as i like but i cannot laminate them ( and no not like running them through a lamination machine) using these materials what bridge would have the most strength but would weigh the least?

depends on if you can bend the wood, if you can, i suggest you use arch, if not, then pratt and howe combo

Just an observation…The Burr Arch (and King Post) design as used in covered bridges in western Indiana not only allow for distribuation of load, but the archs stiffen the truss and stop twist or deflection that can cause a truss to fail.

i am currently workin on a sciencefair project where i will be constructing 3 different bridges.. i am looking for ideas on 1. what 3 designs i should use.. 2. how should I test them as far as which will be able to hold the most weight. and 3 which supplies i should use, hellp mee!

i am working on a science project too. i have to design a scale model of a suspencion bridge. but i am not sure how ro build or design a suspension bridge because i am simply a beginner to all of this. what tyoe of equipment should i use?

I think you should use really thin yarn.

You should probably use balsa wood and wood glue. these materials are really strong and can widthstand a lot of weight.and bridge types such as the parker bridge or the double intersecting pratt bridge are really strong. wow, i feel like a teacher! And im only in 7th grade~!

Hello, i see you need help on your science fair project. I know i’m a little late but i’m here to help. You should make three models of bridges use three different trusses and test what one is strongest.

Your Friend, Juan

I am in the 4th grade and have to make a science project about what type of bridge holds the most weight? All new to me and might as well be a language from another planet. Can any one help? Is ther a formula to use?

The best design would be a cable-stayed bridge-

Here’s an image:

http://www.roadtraffic-technology.com/projects/hangzhou/images/7-cable-stayed-bridge.jpg

However, I am currently doing a project with material that don’t allow this style of bridge or supports in the chasm, so I’m improvising best I can. I originally intended to attempt a suspension bridge, but have since changed it to an eye-looking thing held by triangles that disperse the weight to either side. I wish I had a picture to show you, but our camera is MIA at the moment.

I do not know the effectiveness of this bridge yet, and won’t until Tuesday, but feel free to give it a try if this is the type of project you’re dealing with as well.

in 8th grade making a bridge to hold weights

thats what im doing right now !

i have to make one that’s 11 inches and holds more than 25 lb and i’m in 6th grade

I created an expirement for my fourth grade science fair that tested both the flat truss and the warred truss using the exact same materials; balsa wood and glue. The flat truss held up 46.3 pounds of water, the warren only held 30.9. They both were across a span of eleven inches and in the end I only had chunks of demolished bridge… 🙂

LOL. That would be my result!

What types of materials can you use to make a drawbridge that can hold the weight of many cars at one time?

I haven’t been lucky enough to see many drawbridges but up in Portland Oregon they are mostly steel (the parts that raise and lower)

and concrete at the pillars that hold the bridge up.

For my grade 8 scince fair im dioin a project with bridges and i deffiantly suggest the flat truss!

im in year 7 and i need to build a bridge that has to be 65cm long, 10cm high. it has to be 200 grams it than has to hold the weight of a road that is 750grams and a trolly that has to be 910grams.(it has to be made from dried spaghetti

I am doing an 8th grade science fair project about bridges. How did your project turn out? What type of bridge did you build? How did you do it?

I am thinking of building a bridge out of spaghetti too. I need to gather data, make graphs. I will vary the length of the spaghetti bridge and keep the weight hanging from the center the same and see how length affects its ability to resist breaking. What do you think? I hope I hear from you.

Thanks,

Harry

Does anyone know the strongest type of truss to use for a bridge that will be supporting a hanging a mass in the centre?

Pratt truss…Design simple and build perfect

Usually bridges like the bowstring truss bridge or the double intersecting pratt bridge could hold the most weight, but it depends on what wood you are using. if you are using balsa wood, which is traditional wood for school projects, you would want either triangle or crossing shapes.

I think triangles will hold the most weight.

I tested the popsicle stick versions of the howe, pratt, warren, and k bridges. The bridge that withstood the most weight was the pratt bridge.

sweatland@peoplepc.com I am a welding student and have to build a brige 22 inches long 3 inches wide out of 1/8th in rod. the bridge will be tested by how much weight that can be hung on the underside before it collapses. I plan on an arch brige but am trying to figure the best truss system to use for strength. any feedback would be greatly appreciated. ty ben

If it is not too late, a good system is to have the support beams extend out from the center to evenly spaced points on the arch

Garrett, we recently did a bridge experiment in scouts using card stock to demonstrate how a regular piece will only hold a little weight but the same piece with the long sides folded up a little will hold a lot more. What is the principle being demonstrated? And more importantly, can you use it in Popsicle stick bridge design??

Any one can try this using the front or back from an empty cereal box.

This is a great question and I recently found a youtube video that explains this concept very well:

https://www.youtube.com/watch?v=zSz0kV0BPDY

more detail there are kids that are looking for info

Thanks for the comment, Brenden. We have a lot more detail in our article database covering a wide range of topics related to model bridge building. One article can’t do it all, so we have things split up to focus on certain things.

Do you have anything on a Cable-stayed bridges?

I do not have anything about Cable Stayed bridges at this time.

Girder bridges

Arch bridges

Cable-stayed bridges

Rigid Frame Bridges

Truss bridges.

Which one of these can hold the most weight?

I do have an article about various types of bridges:

https://www.garrettsbridges.com/design/bridge-types/

I did a test between a warren and a string stayed bridge in the end they both broke at twenty five pounds .

I am doing an EPQ about building the strongest bridge and was wondering which it would be? If it is a truss bridge, what materials would I need to physically make one roughly 1-2 meters long?

Thanks

Usually if it is a school project, they would give you balsa wood and wood glue. In that case, you would want to make a lot of triangle or crossing shapes, like a parker bridge or a double intersecting warren bridge. and these are just truss bridges! It all depends on what kind of bridge you are building. (if you do not know what the bridges are that I just listed, you can look them up online.)

Very interesting.. Good read!! #ubi #ulticon #ulticonbuildersinc

So cool I wish I knew this before.

im doing a model truss bridge and was wondering which design would hold the most weight yet be made of the least amount of material. i was thinking the warren.

It is hard to go wrong with any of the designs listed in this article. The key is in your implementation of the design.

I would like a bit more detail because I am doing an assignment on bridges and I have to make a model that can hold a lot of weight. The information wasn’t very precise but it was still very informational.

I’ve reworked this article a bit and added more information, as well as directions for further study.

Worthless article because you don’t answer the question. Pound for pound Howe Truss bridges are worthless when compared against Warren or Pratt. The real question is which is more efficient pound for pound: Warren or Pratt? You do not answer that question.

agreed, I’ve been looking through comments trying to find the answer but haven’t seen any actually credible answers yet.

I think the warren truss is best

How do you know?Did you try the warren design?The website won’t tell us so you can’t be like “The warren truss looks good so I’m going to choose it”

me too i think you are right the warren bridge is the strongesth

OK article I guess

what makes it “OK” instead of good

i really like this website because my challenge teacher Mrs. Simmons really likes us to go to this website every Tuesday and Thursday!

thank you for making this website!

A very helpful article, though the question was not answered.):

Yea, thats what I was thinking too.

I agree with that

Great article, perhaps the different effectiveness of design depends on if the material used in the bridge is better at supporting members in tension or compression? Because if you had a material with a high maximum compression but a low maximum tension you’d surely go with the design that places less stress on the members in tension. Honestly that was what I was looking for when I came here, and after designing my bridge I hope I remember to come back and tell you the answer.

Please do come back and share what you learned!

I’m building a bridge with a bowstring superstructure and a Warren substructure.

What benefits does a substructure add, in your opinion, other than diverting force from the middle to the sides, and is a bowstring truss a better option than a Warren or Pratt?

Do you have a example picture of your design. I want to make sure I understand what you are building before trying to answer.

Thanks for the article, I was reading this to get ready for a competition tonight. This was very useful

What design would you recommend for a bridge building competition, where thin balsa wood sheets are used? We are allowed to use a laser cutter to create it.

You probably don’t want to laser cut your design out of a sheet of wood. The grain of the wood will not be oriented in the best way, and it will be very weak.

The navy uses a built up wood beam for building at Great Lakes. They are about 120′ wide and 1000′ or more in length. Though they do have large blocks of comcrete outside, the same design a multi glued up wood arched beam then just drop lines for your deck. More weight on a arch if ends don’t move the arch just gets stronger.

So if I only have 10 ice-cream sticks, which design would make the strongest bridge yet within the 10 stick limit?

Hi I Made A Warren Truss Bridge with The Side Members opposite To each other(the apex of one triangle faces base of triangle in front)…….will the bridge hold good weight

How do the proportions and angles of the triangles in the truss allow it to function? Does geometry play a role or is it all physics?

Very good information to use for competitions

I’m building a balsa bridge that needs to span 36″. It only needs to hold 25lbs centered. The criteria for winning is to hold 25lbs with the most efficiency. My initial thought was to make an arch super and sub structure that overlaps on the main chord, with warren or K webbing(can post a sketch if it helps). Just wondering if anyone has experience making a bridge of this span length and which truss types work better over such a distance. Thanks!

Thank you for the article, very useful information!

I need to build a small truss ( about 75cm span length between supports, and a maximum height of 25cm) using Balsa wood and glue. It evaluated according to the best strength to weight ratio. Strength being the load that my truss can hold and weight being the weight of my truss. Am I correct to guess that a warren truss will be the best choice?

Thank you!

I have a project this semester on building the lightest yet strongest bridge, and I was wondering what bridge you would recommend. I will be using a 3D printing machine so the bridge will be made that way. The grade will depend on how much weight a bridge can hold while trying to keep it very light.

I don’t have any specific recommendation for a 3D printed bridge. I haven’t printed a bridge yet, or really any strength focused items yet and don’t have enough experience in that area.

3-d printed- go truss bridge with cables 100%, we got like an A+. Just use super strong fishing wire that looks as thick and clear as the normal 6-lb line. (You can also braid it)

What size was the bridge because if it was very light then they were really strong bridges?

Im shawn mendes. can’t answer your question

which bridge design is the best for weight bearing?

I need to make a bridge fast but I do not know how to make one help me make one comment to this to me.

My son just won his school science fair testing the load bearing capacity of a few different bridge designs (beam, Warren truss and an arch bridge) and the arch bridge won, BUT he built abutments (and an abutment frame) to hold the bridge footings in place. An arch bridge, without the use of abutments, will pancake pretty quickly. With those in place, it had a 296/1 strength-to-weight ratio, which I thought was pretty impressive.

Hey guys i was wondering whats better warren truss or prat bridge?